Logistics, Warehousing & Supply Chain

Computer Vision Solutions for Real-Time Visibility, Accuracy & Automation

Modern logistics operations don't fail because of lack of software — they fail because the physical world doesn't match the data in the system.

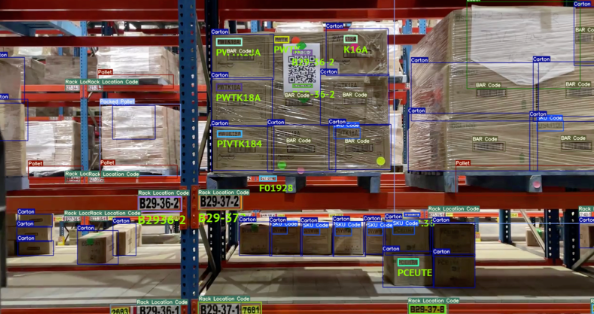

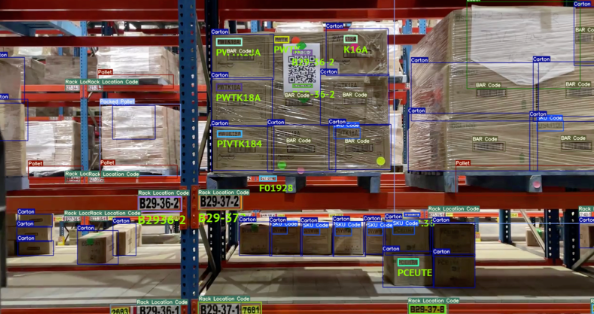

At Kivo Eye, we build computer vision software and AI vision systems that close this gap by watching your operations in real time, detecting what humans miss, and converting video into actionable data — without disrupting workflows.

We work with logistics companies, warehouses, and supply-chain operators to deploy computer vision for logistics, warehousing, and supply chain visibility that improves accuracy, speed, and accountability.

Even with modern WMS and barcode systems, critical blind spots remain:

Inventory shows “loaded” — but was it actually loaded?

A pallet is scanned into receiving — but never shows up in put-away

Cycle counting shuts down operations for hours

A low-value part causes a high-value production line stoppage

Disputes arise over missing or damaged shipments

(Object Counting AI)

This is computer vision for warehousing accuracy at scale.

Know Where Every Item Actually Is

AI Vision for Bin & Part Monitoring

Heatmap-Based Computer Vision Analytics

Instance Segmentation AI

Works in live warehouses, not controlled labs.

Runs on Jetson, Raspberry Pi, or embedded edge devices — no cloud dependency.

Works with existing CCTV infrastructure.

Start small. Expand fast.

As one of the computer vision AI companies focused on industrial deployments, we don’t just sell software — we design solutions around your operations:

If your business depends on:

Accurate inventory

Fast fulfillment

Operational trust

Minimal downtime

Talk to Kivo Eye to deploy enterprise-grade computer vision solutions that turn cameras into 24/7 operational intelligence.